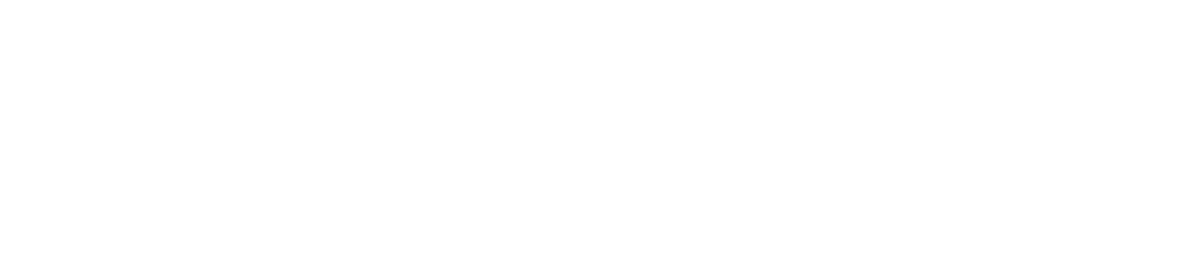

October is a great time to remind customers about the importance of carbon monoxide (CO) detectors. As people start using their heating systems more frequently, the risk of carbon monoxide leaks increases, especially in homes with gas furnaces, boilers, or other fuel-burning appliances. HVAC contractors can emphasize the importance of having functional CO detectors installed in key areas of the home and offer to check or install these devices during routine maintenance visits. This not only enhances safety but also builds trust with customers by showing a commitment to their well-being.

Why Carbon Monoxide Detectors are Important:

- Safety First: Carbon monoxide poisoning can cause symptoms such as headaches, dizziness, nausea, and even death. Having functional CO detectors can provide early warnings and save lives.

- Legal Requirements: In many areas, building codes and regulations require the installation of CO detectors in homes, especially near sleeping areas.

- Peace of Mind: Knowing that their home is equipped with CO detectors can give homeowners peace of mind, especially as they start using their heating systems more frequently.