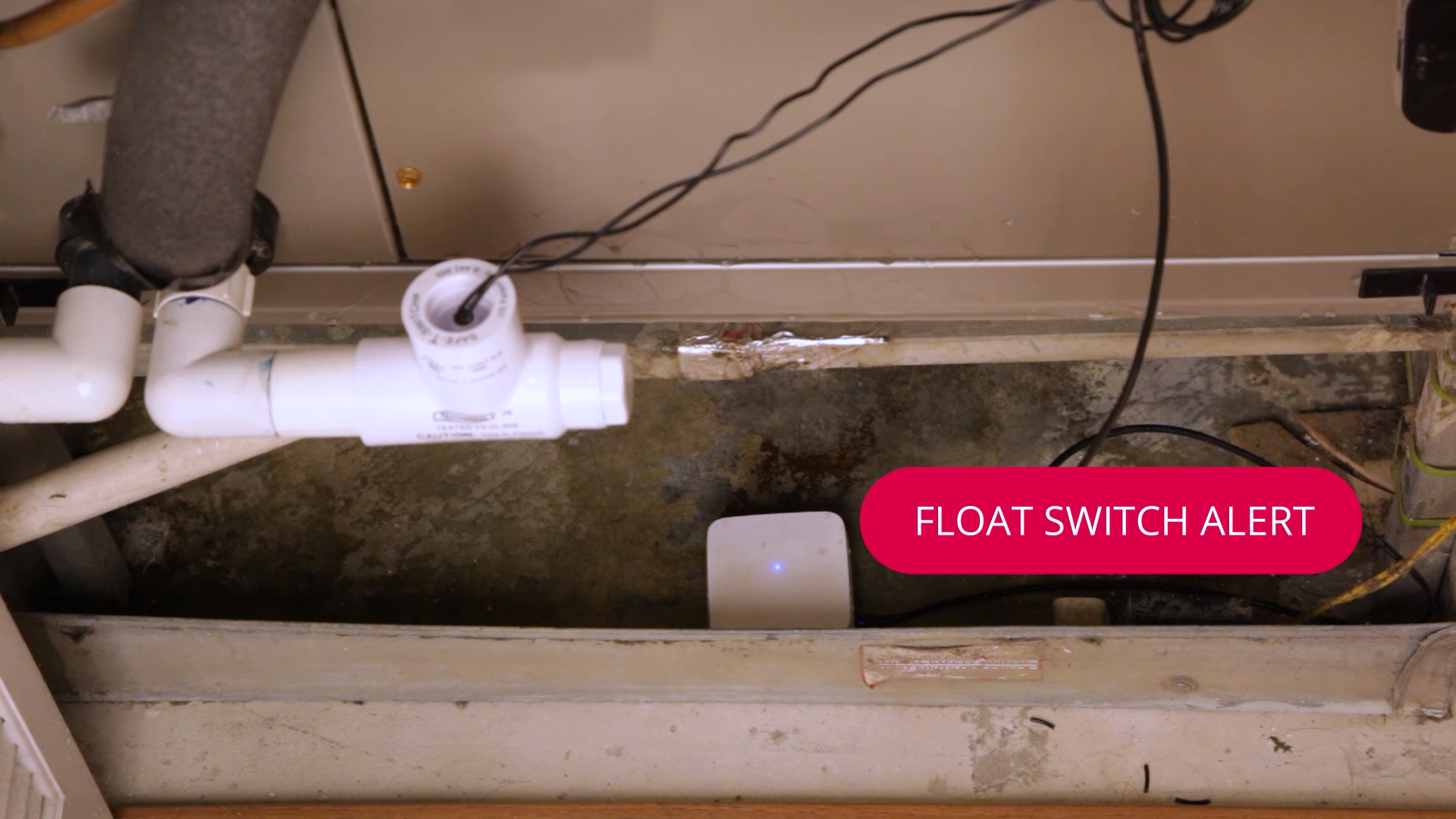

On a recent cold afternoon, I received a call from a frantic service technician. He diagnosed a faulty gas valve in a gas furnace, arrived on the job site with a new gas valve, taken time to ensure the new valve was installed properly, and then observed in horror as the exact same failure to ignite happened with the new valve. Now, let us all be honest with ourselves … after all, nobody is watching … we have all been that technician. We have all experienced the horror of realizing our diagnosis is wrong. Not a good feeling … and far worse if the furnace is in a closet and the homeowner is standing over your shoulder.

After the technician took a few deep breaths and regained composure, we began to go back through the furnace together.

Continue reading “Tech Tips: Diagnosing a Front Cover Switch”