Welcome to 2020.

A New Year offers a fresh start and the hope of a successful year for business. The HVAC industry has been a very quickly evolving industry for many years; that pace does not seem inclined to slow. We face regularly increasing technology in the equipment being offered. Efficiency standards are constantly rising. The pool of quality technicians and installers is constantly shrinking. It really can feel like a roller coaster of a ride sometimes! Let’s look back at a major change in the past year and then discuss what is coming:

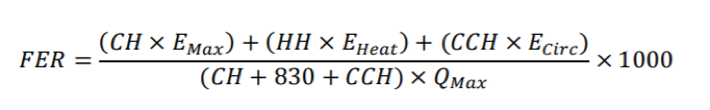

The United States Department of Energy has become a major player in the HVAC industry. The Energy Policy and Conservation Act (EPCA) of 1975 first gave the U.S. Department of Energy (DOE) authority to develop, revise, and implement minimum energy conservation standards for appliances and equipment. EPCA requires DOE to periodically amend energy conservation standards for certain equipment, but only if the amendments are energy-saving, technologically feasible, and economically justifiable. The authority given to the DOE has generally been used to increase the overall efficiency standards of HVAC appliances. The very first efficiency standards for central air-conditioners and heat pumps took effect in 1992 and at that time set the minimum efficiency for these appliances at 10-SEER. In 2019, for the first time ever the DOE enacted an efficiency standard targeting a specific component within the HVAC system: the blower motor. The standard was dubbed “FER” for Fan Energy Rating. It took effect on July 3rd, 2019 and at that time the amount of energy used by the fan motor alone was looked at; manufacturers were required to ensure their equipment contained a fan motor that met this new standard. The FER Standard itself is calculated using a mathematic formula that makes my head hurt:

To break this down in more simplistic terms, the standard mainly effects split system furnaces. There are some other products being affected, but for most HVAC professionals in the residential side of the industry, we consider just a few primary groups of equipment: Furnaces, Air Conditioners, Heat Pumps, Air Handlers, Package Units, and Cased Coils. Of these groups only three use blower motors: Furnaces, Air Handlers, Package Units. Currently, the only group targeted on a large scale by this FER Standard is the Furnace product group. The reasoning here is very straight forward – furnaces operate on 115VAC whereas air handlers and package units operate on 240VAC; the lower the supply voltage the higher the power consumption. So, when we are dealing with a formula that focuses solely on power consumption … furnaces with standard blower motors failed. As a result, HVAC manufacturers had to upgrade the standard blower motors used in split system furnaces. That upgrade took us from PSC blower motors to ECM blower motors; specifically, constant torque style ECM blowers commonly referred to as “X-13” motors. These motors, when used properly, are far more efficient than the older style PSC motors. The efficiency gain created for the motor as an individual component is up to 46%. This should create a system-wide efficiency gain of between 3-7% in many instances.

The FER Standard is another step toward the increasing efficiency of HVAC systems. In 1992 the first minimum SEER rating was 10. That held for 14 years until it was raised to 13-SEER in 2006. Then, we maintained for another 9 years until in 2015 the minimum was raised to 14-SEER for many parts of the country. The next step will be the increase scheduled to take effect on January 1st, 2023. At that time the National Minimum Efficiency for Split System Air-Conditioners, Packaged Air-Conditioners, and Packaged Heat Pumps will increase to 14-SEER with the Southeastern region of the United States seeing an increase to 15-SEER. The entire country will see Split System Heat Pumps move to 15-SEER for minimum efficiency. The industry will continue to evolve. Central air-conditioning that was once considered a luxury is now viewed as essential. Technology and efficiency will continue to increase. Components that many of us are comfortable with like capacitor driven motors, fixed orifice metering devices, and simple 24VAC controls will disappear as they are replaced with more advanced components to support the high-efficiency needs of the products.

The good news in all of this is that the HVAC industry from a business standpoint will stay strong for the foreseeable future. I personally feel that the next 10-years will be better than the last 20-years in terms of business potential. We have a public that expects comfort in their homes. We have continually improving equipment to meet the continually climbing energy standards. We have a very limited resource in the people that can install and service these HVAC systems. For the people who can adequately manage their time while delivering a good experience to the consumer, business, as well as profits, should be very strong in the coming year and beyond.