As cold weather approaches and heating season enters, HVAC professionals might see an increase in service calls from customers who say that their heat has stopped working or won’t turn on. One of the most common problems identified is heat sequencer failure.

Several issues can contribute to the failure of this part:

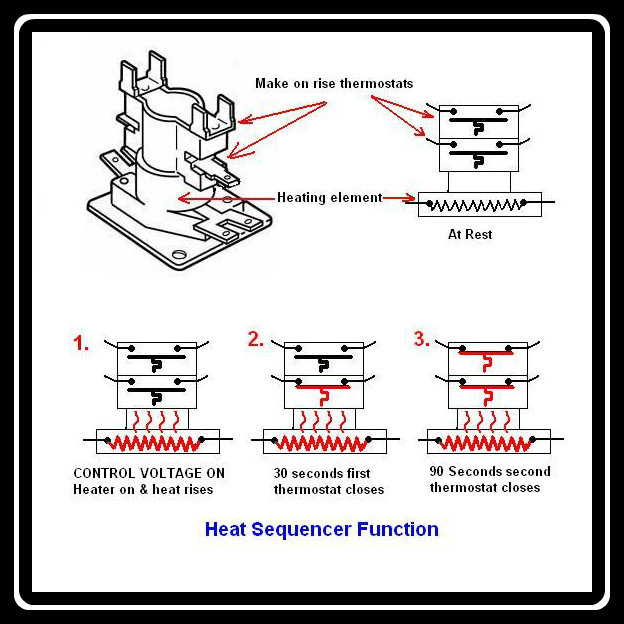

- Frequent use throughout the season causing flexing and straightening of the bimetal switch. Sequencers are basic relays that use a heater coil and a bimetal switch. Control voltage is applied to the heating coils which heats the bimetal switch. This is essentially a thermostat which rises when heated. The heat causes the bimetal switch to flex, making contact across the switch and sending power to the elements.

- Bimetal switch is stuck either in the open or close position. Heat sequencers are designed to either turn on or off the heating elements in a furnace in a series of delays. This is so that they do not all come on at the same time, which would cause a surge of current that could trip a breaker. A sequencer delay can be 30 seconds or up to 90 seconds, depending upon the settings of the individual sequencer.

- Extended disuse, such as during the summer months.

Luckily, this is an inexpensive repair and part of a system’s normal wear and tear. Due to the frequency of this part’s failure, this item is an essential item to have in your truck stock inventory at all times throughout the cold months of Autumn and Winter.