As the summer heat slowly begins to fade, the cool breeze of fall will meander into the area. Many of us will begin to shift our focus to heating equipment check-ups. These can be a bit monotonous in the early days of fall, but the most important time to check a heating system is before it endures regular run time through the winter.

A crucial area that is often overlooked on a gas furnace is the temperature rise. The temperature rise across a gas furnace is like ensuring that your vehicle has plenty of coolant in the radiator. Furnaces, much like engines, do not like to run hot!

A good temperature rise will come down to two factors:

- The amount of fuel burned.

- The amount of air moved.

Every manufacturer lists the acceptable range of temperature rise across the gas furnace. This will usually be in a range close to 30-60 degrees. The ideal “sweet spot” is the middle of the given range. Maintaining a good middle range temperature rise provides the following benefits:

- Good, warm air flowing from the ducts.

- Good fuel burning efficiency.

- Proper operating temperature of the furnace.

- Good even cycling.

Setting the Temperature Rise

- Find the nominal gas pressure listed on the furnace’s data plate. A classic example would be 3.5″ w/c for natural gas.

- Set the airflow to closely resemble the cooling airflow.

- Cycle the furnace for roughly 15 minutes to allow temperatures to stabilize.

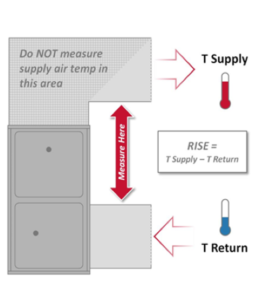

- Take a temperature reading in both the supply and return duct trunks. Ensure that the supply reading is taken “out of line of sight” from the heat exchanger.

- Once the temperature rise is known, make adjustments to either outlet gas pressure or airflow to set it to your desired rise.

- Take care to keep adjustments within manufacturer specifications.